MEDIA LIBRARY

The media library contains publications, videos, and photos about PACCOR.

Terms of use for PACCOR press pictures

PACCOR press pictures may only be used for editorial purposes. Unless otherwise stated, all copyrights and rights of use and exploitation are owned by PACCOR Packaging GmbH, Ravensburg (Germany), or by one of its affiliated companies. The reproduction and publication of PACCOR press pictures is only permitted if the source is stated as follows: "Image: PACCOR". The pictures may be used free of charge in such cases. The use of pictures for advertising or other commercial purposes, in particular their disclosure to third parties for commercial purposes, is hereby prohibited. Pictures may only be edited with the approval of PACCOR.

We kindly request that a specimen copy be sent to us when PACCOR press pictures are published in printed media (or a digital copy in the case of publication in electronic media). When using PACCOR press pictures in films, please notify us and state the title of the film.

Use and utilization of PACCOR press pictures are subject to the substantive laws of Germany without its conflict of law provisions. The place of competent jurisdiction shall be Ravensburg, Germany.

By downloading a PACCOR press picture, I accept these regulations as binding.

Postal address:

PACCOR Packaging GmbH

Schubertstrasse 27

88214 Ravensburg

Germany

The DuoSmart® tray

The DuoSmart® tray

The PACCOR DuoSmart® Tray can be produced from PP/rPP or PET/rPET with a cardboard sleeve. It is ideal for packaging meat, fish, ready meals, salads, and vegetables.

Learn more about the hybrid tray here.

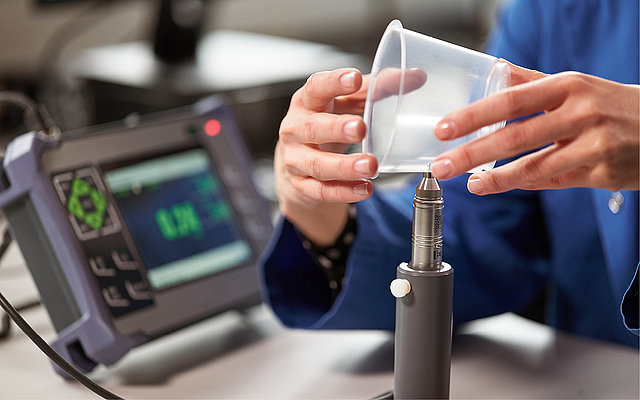

PACCOR’s Center for Development & Innovation (CDI)

PACCOR’s Center for Development & Innovation (CDI)

PACCOR’s team of designers, engineers, testing specialists, and market advisers work closely together to make sure the products meet the highest quality demand levels. PACCOR is able to provide unique one-stop services for food and non-food manufacturers around the globe.

PACCOR’s Center for Development & Innovation (CDI)

PACCOR’s Center for Development & Innovation (CDI)

Whether it is a unique shape, material, or design, in PACCOR’s Center for Development & Innovation we find a solution for every wish and need of our customers. PACCOR monitors the manufacturing cycle and makes sure it goes through extensive testing to ensure a high-quality end product.

PACCOR’s Center for Development & Innovation (CDI)

PACCOR’s Center for Development & Innovation (CDI)

PACCOR guarantees innovative sustainable packaging development, speed to market, and unique one-stop services for food and non-food manufacturers around the globe.

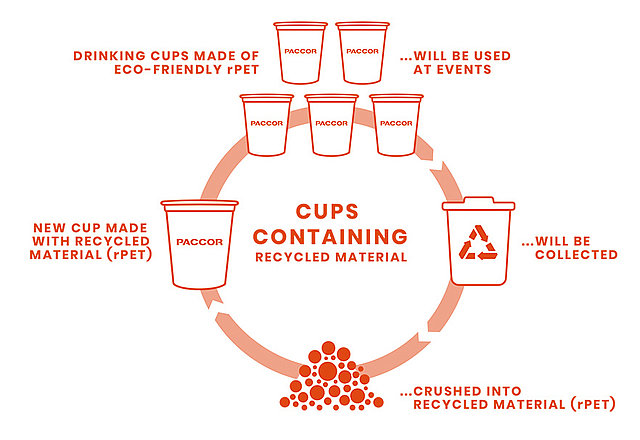

PACCOR‘s “Circular Events”

PACCOR‘s “Circular Events”

PACCOR‘s “Circular Events” generate sustainability awareness and provide the opportunity to turn single-use plastic products into valuable resources for future products.

Mr. Kilian Braunsdorf, PACCOR’s Chief Executive Officer (CEO)

Mr. Kilian Braunsdorf, PACCOR’s Chief Executive Officer (CEO)

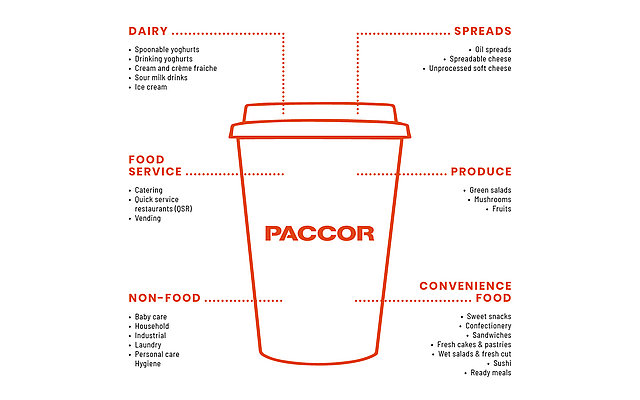

Cups and lids – PACCOR’s packaging solutions for food service

Cups and lids – PACCOR’s packaging solutions for food service

Varied shapes and sizes of bowls, pots, and containers to store different products. Perfect for confectionery, deli, desserts, ice cream, salads, prepared fruit, yogurt.

PACCOR’s tumblers and lids rPET range

PACCOR’s tumblers and lids rPET range

Fully compatible with the circular economy concept. This mono material packaging is reducing the use of plastics and fully recyclable into new plastic packaging. High quality printing is an option to emphasize brand identification even further.

DeliCircle rPET range

DeliCircle rPET range

100% rPET, reclosable, safe, and easy to handle makes DeliCircle the ideal companion for on-the-go consumption. DeliCircle has been designed that consumers can act more responsibly towards the environment without giving up their favorite dishes and having to cook everything at home.

DeliSeal rPET range

DeliSeal rPET range

Sealable pots intended for industry. Fully recyclable into new plastic packaging thanks to PACCOR’s post-consumer PET decontamination technology.

Tri-Pots rPET range

Tri-Pots rPET range

The pots can be heat sealed for greater food protection and shelf life. Truly sustainable packaging solution – 100% recyclable material.

DeliGreen™ rPET range

DeliGreen™ rPET range

100% recyclable, built-in internal decontamination system to promote the circular economy, DeliGreen™ satisfies the demands of today’s foodservice industry – sustainable, practical, and modern bowls.

Wave container rPET range

Wave container rPET range

PACCOR aims to produce its packaging in a sustainable way. Multi-capacity shapes enable every customer to make a perfectly-optimized choice – black base creating a premium image and Eco-friendly as made from rPET.

Vision container rPET range

Vision container rPET range

The nomad container of responsible consumers, made of 100% recycled PET, recyclable. A fantastic clarity maximizes the presentation, a with strong emphasis on product visibility. A modern and minimalistic design guarantees excellent merchandising value.

rPET punnets

rPET punnets

The packaging offers superb transparency in both punnets and lids, making the content perfectly visible and attractive to consumers. Punnets guarantee the best product safety throughout the supply chain. Integrated air holes allow for faster cooling and improved air circulation, giving the product longer shelf life.

High barrier PP single serve pods

High barrier PP single serve pods

The proprietary material structure allows for excellent welding properties for both lids and filters. PACCOR's PP pod is reclaimable in a material recovery facility (MRF) based on a material density that allows it to float.

Barrier coffee capsules

Barrier coffee capsules

A convenient product that provides excellent coffee. PACCOR has developed together with its clients a high-performance capsule that meets first the aroma barrier for the coffee and, finally, a demanding and excellent brew of the coffee.

OPP sleeved cup – mono material solution

OPP sleeved cup – mono material solution

Basic functions of sleeves: decoration, information, protection; it is ideal to make product apparel unique through a differentiated decorating solution.

DuoSmart® for dairy products

DuoSmart® for dairy products

Modern packaging that combines the attractiveness of paper with the functionality of plastic. DuoSmart® packaging contains up to 50% less plastic, and with a “zip” option, the inner cup and sleeve can be easily separated into different waste streams.

DuoSmart® for pet food

DuoSmart® for pet food

Modern packaging that combines the attractiveness of paper with the functionality of plastic. DuoSmart® packaging contains up to 50% less plastic, and with a “zip” option, the inner cup and sleeve can be easily separated into different waste streams.

DuoSmart® for cereals

DuoSmart® for cereals

Modern packaging that combines the attractiveness of paper with the functionality of plastic. DuoSmart® packaging contains up to 50% less plastic, and with a “zip” option, the inner cup and sleeve can be easily separated into different waste streams.

DuoSmart® for instant food

DuoSmart® for instant food

Modern packaging that combines the attractiveness of paper with the functionality of plastic. DuoSmart® packaging contains up to 50% less plastic, and with a “zip” option, the inner cup and sleeve can be easily separated into different waste streams.

DuoSmart® for convenience food

DuoSmart® for convenience food

Modern packaging that combines the attractiveness of paper with the functionality of plastic. DuoSmart® packaging contains up to 50% less plastic, and with a “zip” option, the inner cup and sleeve can be easily separated into different waste streams.

PACCOR’S IM-IML LABEL DESIGN

PACCOR’S IM-IML LABEL DESIGN

This is a composing of PACCOR’s current IM-IML label design for the new cup size of 150g.

PACCOR production

PACCOR production

PACCOR enables efficient production runs with consistent quality and a reliable output. We currently have an extensive capacity for high-speed thermoforming that meets our customer needs and offers a broad range of both standardized and customized packaging.

PACCOR production

PACCOR production

Our employees are proud of working for PACCOR. Our corporate culture is best described as learning from each other, understanding different perspectives, including them into creating solutions, feeling valued, and bringing inspiration by defining new paths.

PACCOR production

PACCOR production

PACCOR’s manufacturing site in Hämeenlinna, Finland

PACCOR production

PACCOR production

We are a diverse group of over 3,000 employees who live and work in many different countries and cultures throughout Europe and North America. It is extremely important to us that all employees have equal rights and the same possibilities and opportunities.

PACCOR production

PACCOR production

PACCOR’s quality assurance in our site in Siemianowice, Poland.

The DuoSmart® Tray

The DuoSmart® Tray

Watch this video to learn how the DuoSmart® Tray gives you the best combination of practicality and sustainability in one package.

Furthermore, learn why it is the next best choice for your product.

PACCOR's new DeliTwist portion pots and lids

PACCOR's new DeliTwist portion pots and lids

Sustainability Report 2021

Sustainability Report 2021

The PACCOR Sustainability Report 2021 shows what sustainability means, especially for our employees. Thanks to our highly skilled and engaged workforce, we are demonstrating that a circular economy in plastics is possible in practice and at scale.

The DuoSmart® Tray

The DuoSmart® Tray

Learn more about the PACCOR DuoSmart® Tray in the leaflet below.

the future of beverage service solutions - PACCOR Beverage Solutions Booklet

the future of beverage service solutions - PACCOR Beverage Solutions Booklet

PACCOR's 2020 Sustainability Report

PACCOR's 2020 Sustainability Report

PACCOR's 2020 Sustainability Report provides a transparent and detailed overview of the company’s sustainability work in each of its four strategic fields of action: Circularity, Alliances, Resources, and Employees.

The report was compiled in accordance with the guidelines of the Global Reporting Initiative (GRI).

PACCOR - How we create value

PACCOR - How we create value

Plastic packaging is part of the sustainable society.

Read more in our 3-dimensional profit & loss (3D P&L) assessment on PACCOR packaging solutions with Digimarc technology.

Sustainable Coffee Pod Solutions - PACCOR Coffee Booklet

Sustainable Coffee Pod Solutions - PACCOR Coffee Booklet

The Future of Dairy Solutions – PACCOR Dairy Packaging Booklet

The Future of Dairy Solutions – PACCOR Dairy Packaging Booklet

The Future of Food Service Solutions – PACCOR Food Service Solutions Booklet

The Future of Food Service Solutions – PACCOR Food Service Solutions Booklet

The Future of Ready Meals - PACCOR Ready Meals

The Future of Ready Meals - PACCOR Ready Meals

The Future of Protein - PACCOR Protein Booklet

The Future of Protein - PACCOR Protein Booklet

The Future of DuoSmart® - PACCOR DuoSmart® Booklet

The Future of DuoSmart® - PACCOR DuoSmart® Booklet

Valuing Plastics – A Literature Review