Dairy

MEETING THE HIGHEST DEMANDS

Nowadays, consumers can find everything their heart desires on supermarket shelves: from yogurt, cheese, and pudding to spreads, desserts, and ice cream. Each of these delicate products has its own special characteristics, which must be taken into account when developing a customized packaging solution. In addition, it must not be forgotten that consumers have ever higher demands on packaging – multifunctional, flexible, attractive design and options for on-the-go.

To protect a product in the best possible and most efficient way, our customers often need an individual solution that goes beyond the standard. Our team of experienced specialists advises our clients throughout the entire development and production process. When developing a tailor-made solution, we pay attention to a co-development process with holistic consulting, fit-to-purpose development, and a fast market introduction – from idea generation to packaging supply. We help our customers to make the perfect choice to protect the nutritional value, color, aroma, and taste of their products.

Duosmart

FEATURES AND BENEFITS

- offer a high standard in food safety and product presentation

- perfect choice to protect the nutritional value, color, aroma, and taste of food products

- various material options for insert and paper segment

- hot filling and microwaving are also options

- zipper for easy separation of paper and plastic

Please find a printable version of our Leaflets in our Media Library/Publications.

THE PERFECT COMBINATION OF PAPER AND PLASTIC

FOR MULTIPLE USAGE IN ALL FOOD & PACKAGING SECTORS

Extruded rigid sheets

Features and Benefits

- numerous decoration options

- outstanding gas barrier properties

- good processability

- microwaveable, aseptic, sterilization pasteurization

- better, longer shelf life

FFS Application FOR THE DAIRY INDUSTRY

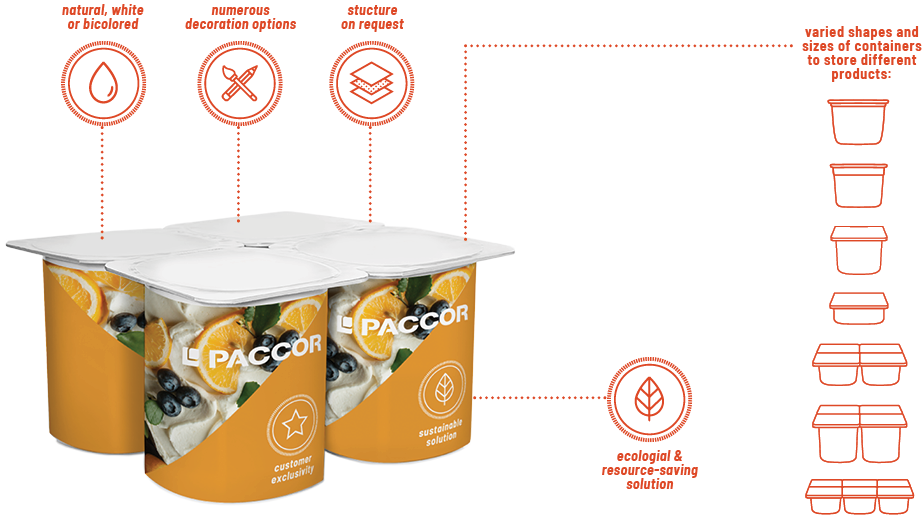

Thermoformed cups & tubs

Features and Benefits

- dry offset printing in DLE technology – Direct Laser Engraving: sharper and brighter print results

- revolutionary T-IML technology: IML decorated, barrier, and resortable plastic packaging solutions for products with a longer shelf life

- modular insert technology with lower tooling costs

- high standards of food safety labeling and product presentation

Please find a printable version of our Leaflet in our Media Library/Publications.

Sleeved Cup

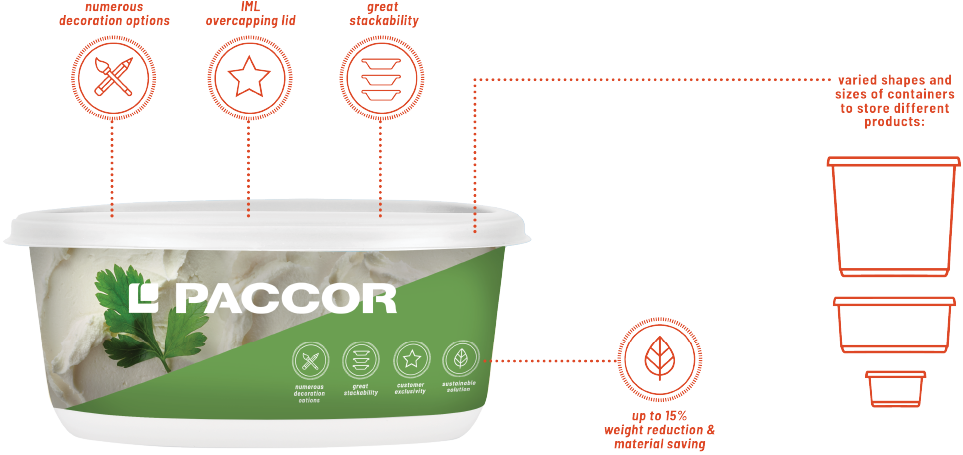

Injection Molded Containers

Features and Benefits

- highest decoration possibilities and shelf impact, freedom of form and function

- eco-friendly technology by energy saving through the production process

- compression technology: less material usage and longer tooling life

- compact and simple shapes generate great stackability and maximize the shelf space

DAIRY PACKAGING TUB

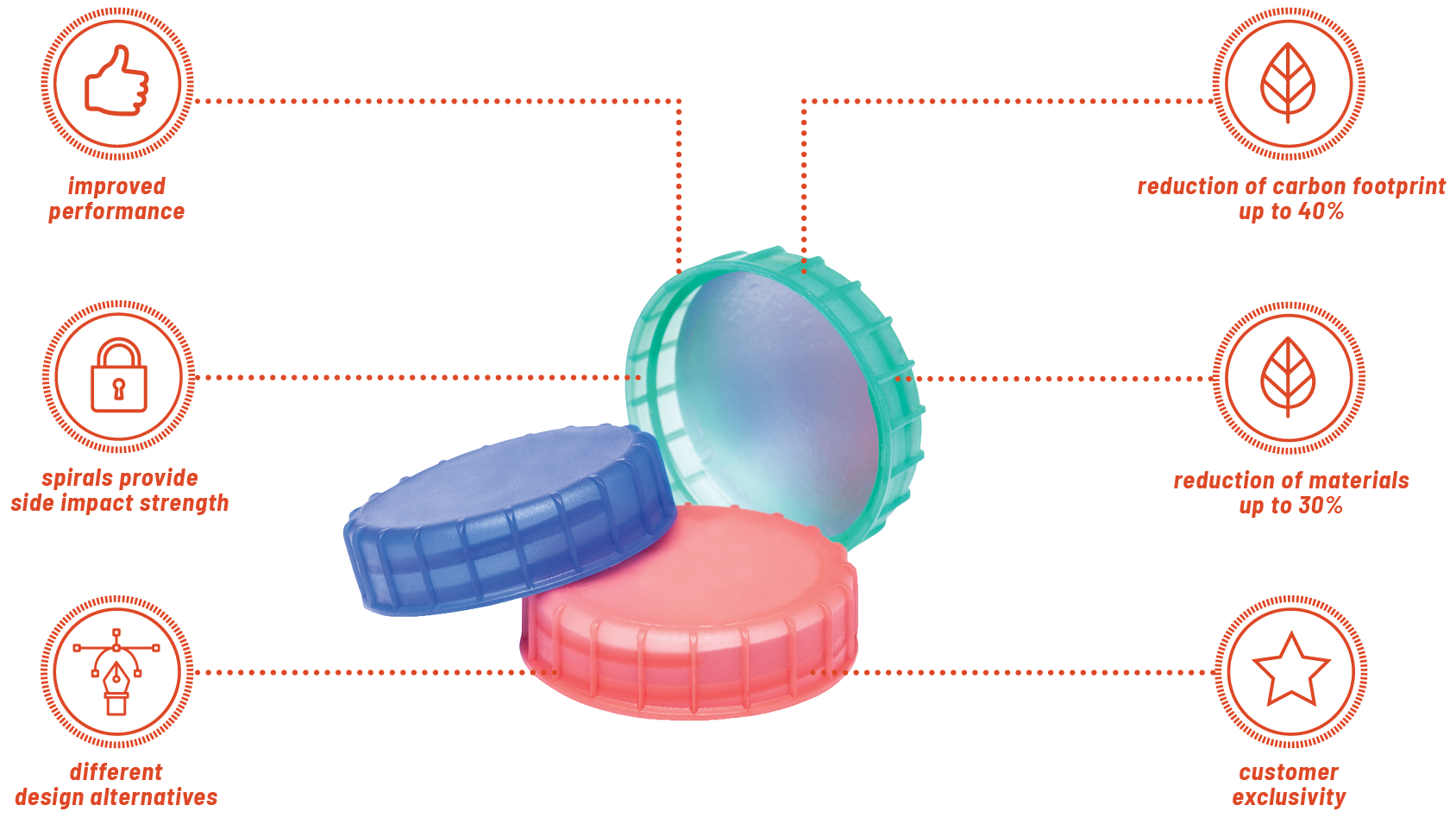

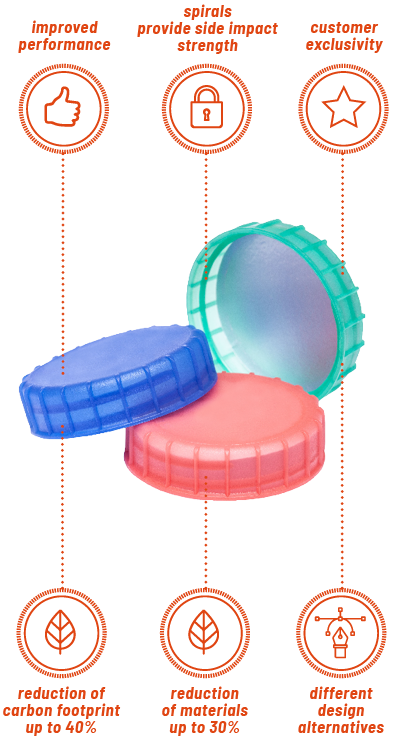

Continuous Compression Molded closures

Features and Benefits

- enables up to 20% weight reduction through a decreased wall thickness

- higher accuracy and lower tolerance levels in the production process resulting in improved performance on customers‘ filling lines

- available in a variety of formats including tamper-evident, induction heat seals, single-piece bore seals, and EPE lined

- different design alternatives such as embossing, debossing, surface finish variation can be a very cost-effective means of offering brand identity

CAPS & TOP CLOSURES