PACCOR DRIVES THE TRANSFORMATION TOWARDS EFFICIENCY

PACCOR values future resources, which can be observed through our highly engaged workforce and explicit value agenda, as well as through our leading position in the sector transition towards carbon neutrality by 2050. We are transforming our business and decoupling it from resource constraints.

Our CARE strategy is about creating a culture that cares for all the materials we use, eliminating waste and reducing variable costs.

It is about increasing resource efficiency in our operations and making our supply chain more sustainable, as well as minimizing risks.

Our ambition is to be a circular business built on renewable energy and recycled resources, decoupling material use from our growth. In line with this, PACCOR is driving a resource efficiency agenda, reducing our environmental footprint while strengthening our business.

MAIN TARGETS FOR RESOURCE EFFICIENCY

15% more efficient resource use across the value chain by 2025, compared to baseline year of 2019

10% relative energy reduction in own production by 2025, compared to baseline year of 2019

25% reduction of total waste in relative terms by 2025 compared to baseline year of 2019

RESOURCE FOCUSED ACHIEVEMENTS

To quantify and track the transition towards a fully carbon neutral plastic packaging value chain by 2050, we have completed our first cradle-to-grave carbon footprint reporting for the entire company for the year 2019, according to the Greenhouse Gas (GHG) protocol.

We are very proud to have a closed cooling water system at all our sites. We manage water consumption by measuring water balance and assessing risks and corrective actions related to water sources, the security of supply, efficiency, quality of discharges, and regulatory compliance.

As of 2020 and over a period of three years, we have committed ourselves to achieve an increase in our renewable electricity share to 100% at all our sites, through Certificates of Origin purchase. Currently, renewable energy already has a 64% share, with 8 out of 16 plants running entirely on renewable energy.

We have moved the focus from managing waste to eliminating waste. PACCOR Iberia, for example, has been investing heavily in the “closed loop system concept” and achieved the net minimum net scrap cost of 1.1% of sales during 2019.

Our Route towards Carbon Neutrality

Carbon Footprint

By 2025, PACCOR is set to become a circular business operating on renewable energy and recycled materials. To achieve this goal, we are continuously overseeing our operations and analyzing our life cycle, which consists of our suppliers, customers, and the end-of-life of the goods. We do this to identify hotspots and to regulate our improvement roadmap, where we are prioritizing programs and resources to create a substantial impact within the industry and towards the benefit of the environment.

Our goal is to reduce PACCOR's carbon footprint from cradle to grave by 15% per tonne of sales between 2019 and 2025 while growing PACCOR business.

PACCOR's Zero-Waste Policy

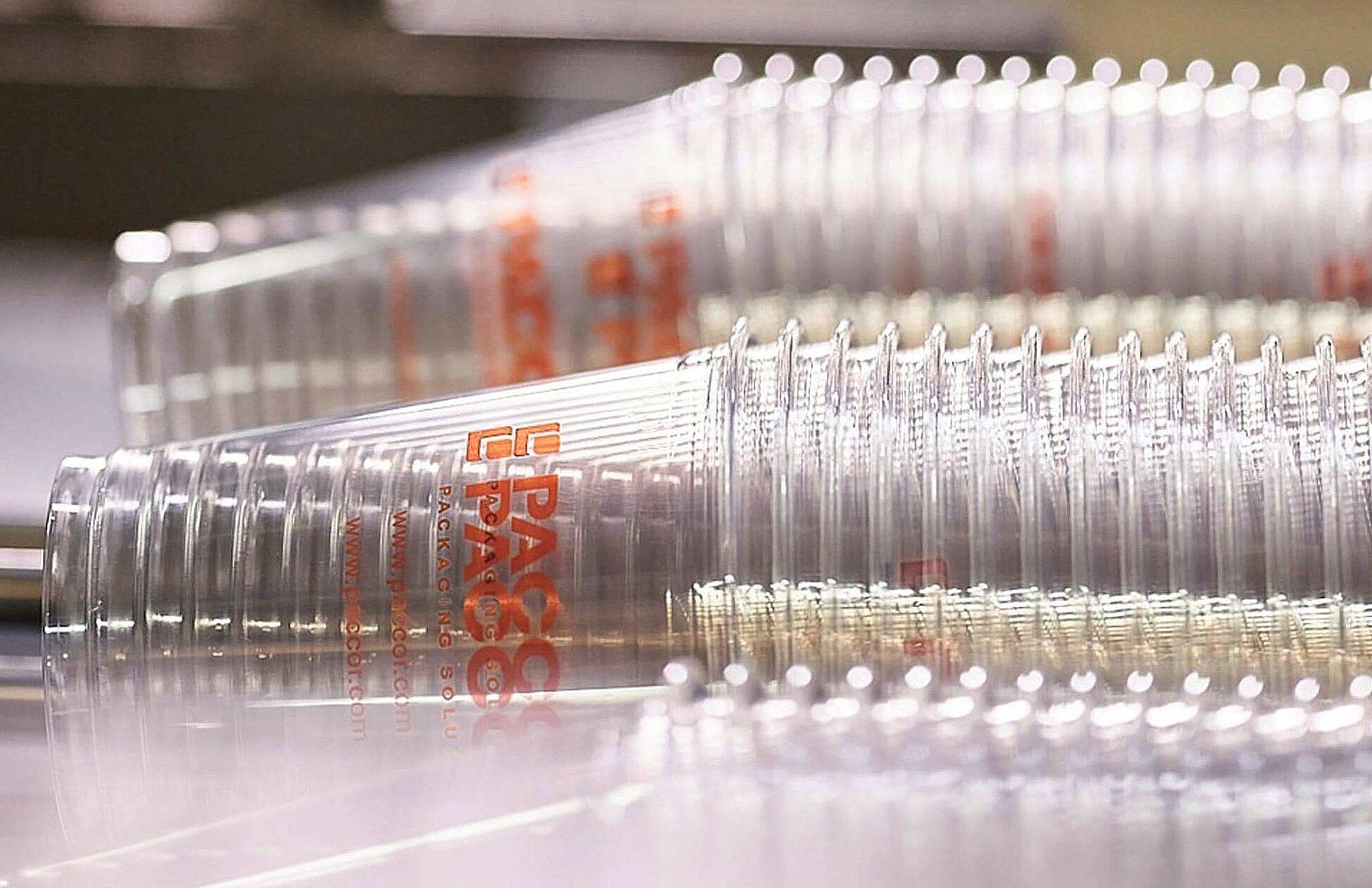

Over the coming years, PACCOR focuses on implementing a zero-waste policy throughout its production sites. Our resource efficiency agenda helps to increase raw material efficiency in our manufacturing operations, reducing our environmental footprint as well as costs.

Since our aim is to eliminate waste, we are focusing on reducing hazardous waste to landfills and better conversion of raw materials into final products at all our sites. Through our participation in the "Operation Clean Sweep®", 2019, PACCOR’s sites were able to reduce the loss of resin raw materials and increase yields significantly.

One of our greatest achievements and proof that PACCOR is a goal-achieving sustainable packaging company, is the fact that all our sites have a closed cooling water system.

Other commitments we are making towards achieving our goal

To achieve climate neutrality, by 2050, we are contributing to this aim through innovative products and solutions, as well as technology and energy management with:

- more raw materials that have a lower footprint, are biobased or recycled.

- improved energy efficiency and generation, as well as the use of 100% renewable electricity at all our production sites.

- usage of low-emission transportation options for our raw materials and final products.

- advanced eco-design production that allows full recyclability of our products at their end of life.

- reduction of our carbon footprint by minimizing travel, usage of green appliances, and usage of sustainable web hosting services.