TURNING CHALLENGES INTO SOLUTIONS

Plastic packaging plays an important role in our everyday lives, it protects our food, drinks, hygienic products, and many other important goods that we use daily. It is a protective equipment with a high safety provision level, that other materials have a hard time achieving. Unfortunately, there is a persistent issue the plastic packaging industry is dealing with, and specifically that the current plastic system is struggling and not performing properly.

This is why PACCOR made its top priority to move away from a linear plastic economy towards a circular economy.

The change starts with PACCOR itself, that is why we are changing not only our design process, but also how we produce, dispose of and reprocess plastics.

OUR ACTIONS SPEAK LOUDER THAN WORDS

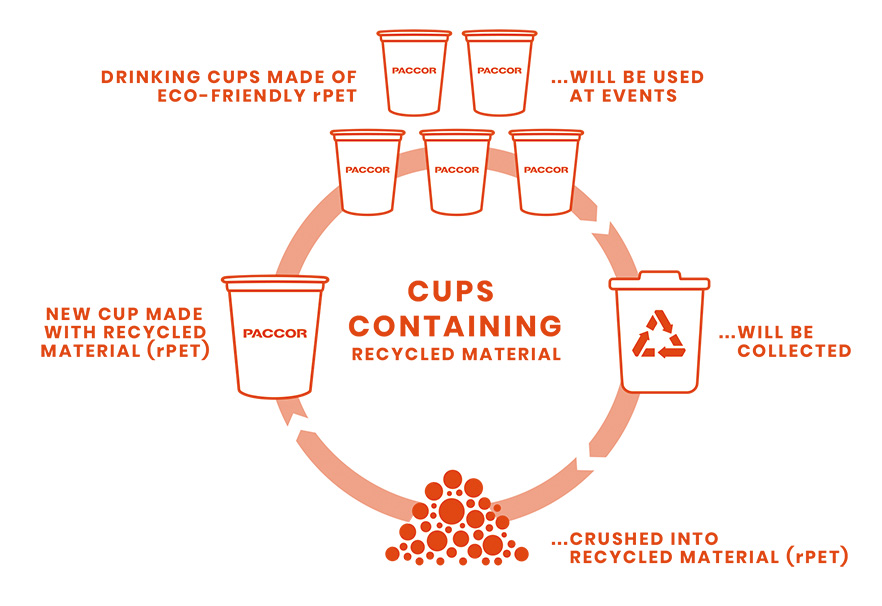

‘Circular Events’ is the new PACCOR project, that generates sustainability awareness and provides the opportunity to turn single-use plastic products into valuable resources for future products. It creates a positive impact and awareness on what circularity means.

The entire process is composed of the following steps: beverage and food plastic containers used during big assemblies, such as music concerts, shows, and sporting events are collected and transported to specialized recycling partners. They are then crushed and recycled, in order to make sure they do not end up in landfills or incinerated. Afterward, the material will be used in PACCOR’s manufacturing sites to produce new cups containing recycled material, closing the loop of our drinking cups.

PACCOR's Circularity Targets

CREATING A VIRTUOUS CYCLE

As a leader in the French market, we moved the standard (PS) of this market to eco-designed recyclable and recycled PET lids, which contain recycled material. This has led to a direct reduction of 200 tonnes of raw material consumption and consequent reduction of the product carbon footprint impact.

65% of our packaging range is recycled in practice and at scale.

Our new concept “Circular Events” creates a positive impact and awareness on what circularity means in practice by giving the organizers of events the opportunity to turn single-use plastic products into valuable resources for future products.

Our embossed "I'm Recyclable" series PET cups which contain recycled material are an example of circularity in practice. We have reduced the weight up to 25% compared to similar-functioning cups. Thanks to the embossing technology instead of using labels, they can be recycled at the end of life and reused as material in food applications.

PACCOR and The New Plastics Economy Global Commitment

On June 17th, 2019, PACCOR was among more than 450 organizations that have signed The New Plastics Economy Global Commitment. Among the signatories, we were joined by an impressive range of the world’s largest packaging producers, brands, retailers, and recyclers, as well as governments and NGOs. One of the main goals of the treaty is to eradicate plastic waste and pollution. It requires that 100% of plastic packaging be easily and safely reused, recycled, or composted by 2025.

PACCOR, joined by our business partners, takes this commitment exceptionally seriously. For us, it translates into creating priorities that regard:

- Optimizing product design and material use thus creating innovative solutions to deliver truly circular solutions.

- Increasing the amount of recycled materials made into new products.

- Developing and offering sustainable packaging solutions without compromising food safety, while respecting the health, safety, and rights of all people involved.

- Constantly improving our processes.

OUR ROUTE TOWARDS A CIRCULAR FUTURE

PACCOR’s circular solutions concept requires the assessment of several sustainability aspects along the value chain. Therefore, life cycle thinking is the basis for our sustainability approach, and as of 2019, has been included in a range of processes developed and validated by the European Commission. One of them is the calculation of our products and services' total environmental performance throughout their life cycle.

While focusing on the minimization of climate change and resource use, we simultaneously aim at reducing our product's overall environmental footprint. This way confirming the fact that life cycle assessments are integrated into the company’s innovation and major investment processes.

PACCOR’s efforts to achieve its goals are assessed and overseen by Group level specialists and external consultants, referring to ISO 14040-44.