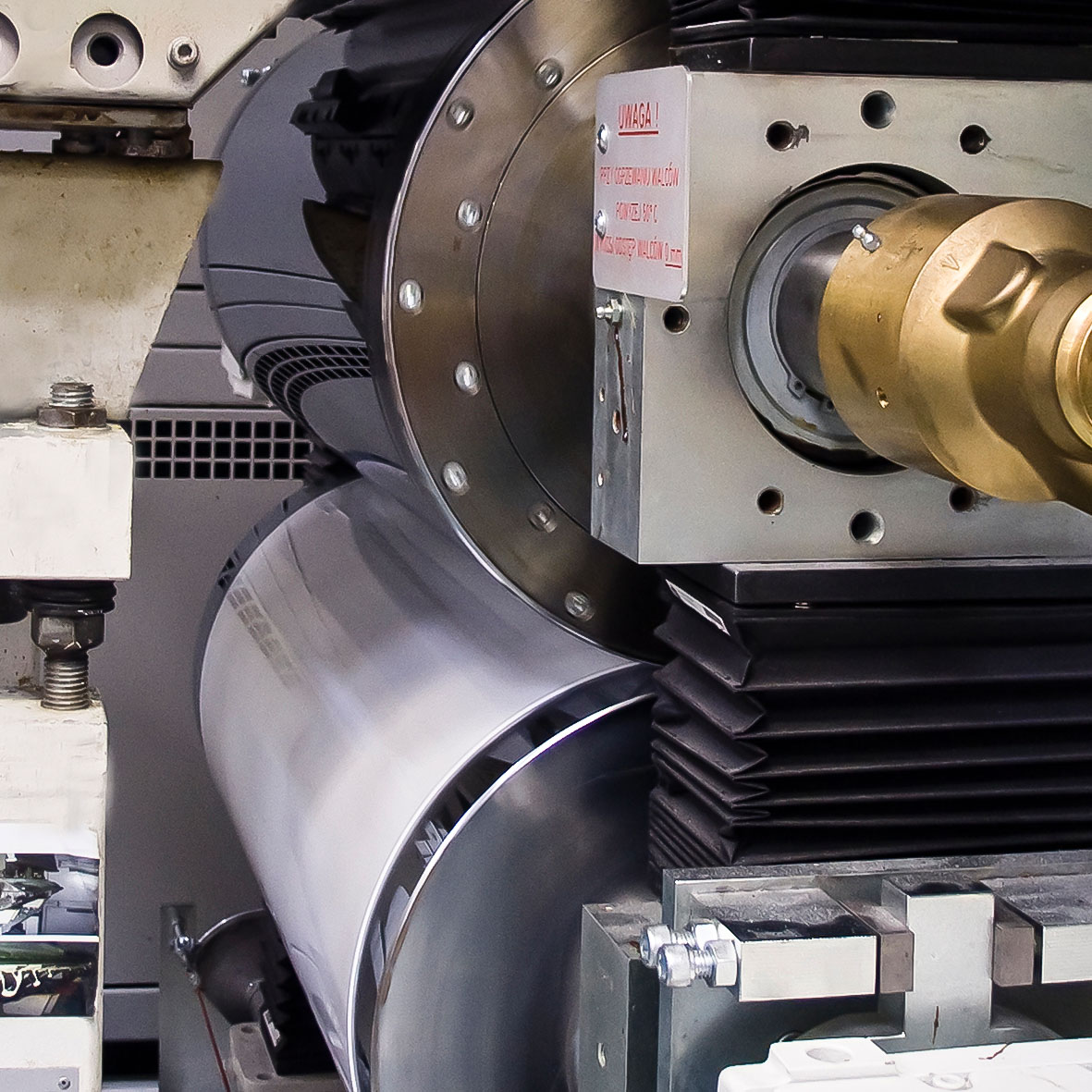

Extrusion

Plastic sheet extrusion is one of the most important processes in our Group. We extrude all the necessary mono- and multi-layer sheets for our thermoforming requirements, as well as complex sheets sold for Form-Fill-Seal applications (FFS; dairy and high barrier). Co-extrusion is used to apply one or more layers on top of base material to obtain specific properties such as UV-absorption, texture, oxygen barrier, or energy reflection.

OUR SOLUTIONS FOR:

| Dairy | Form-Fill-Seal sheets in single or bi-color structures |

| Rigid sheets for thermoforming | |

| Fresh Food | PET and PET/PE Form-Fill-Seal sheets |

| Convenience Food | High-barrier multi-layer sheets for FFS applications |

The main materials we are processing are PP, PET, and PS.

Thermoforming

Thermoforming is our core process. By focusing on this process, we enable efficient production runs with consistent quality and reliable output. We have an extensive capacity for high-speed thermoforming which meets customer needs and offers a broad range of both standardized and customized packaging for food and non-food applications. In everything we do, we focus most on your products, which is why we offer thermoformed packaging in a wide range of thicknesses and colors.

Our Solutions for:

| Dairy & Ice Cream | Thermoformed cups decorated with dry offset, shrink sleeves, labels, or embossing |

| Thermoformed reclosable lids | |

| Food Service | Cups and lids |

| Multi-fresh containers and hinged lids packs | |

| Catering and gourmet trays and lids | |

| Deli and pastry trays and lids | |

| Fresh Food | Thermoformed trays with color, embossing and lamination options |

| Thermoformed salads, prepared vegetables and fruit packs | |

| Punnets | |

| Convenience Food & Spreads | Thermoformed trays, pots, bakery liners, tubs |

| Thermoformed lids printed or pre-printed | |

| Coffee capsules |

PP foaming

The PP foaming technology allows a 10 to 15% weight reduction of the products with full skeleton reincorporation and increased thermoforming cycle time.

The solutions improve shelf life at lower carbon costs, thus contributing to the well-being of people and our planet.

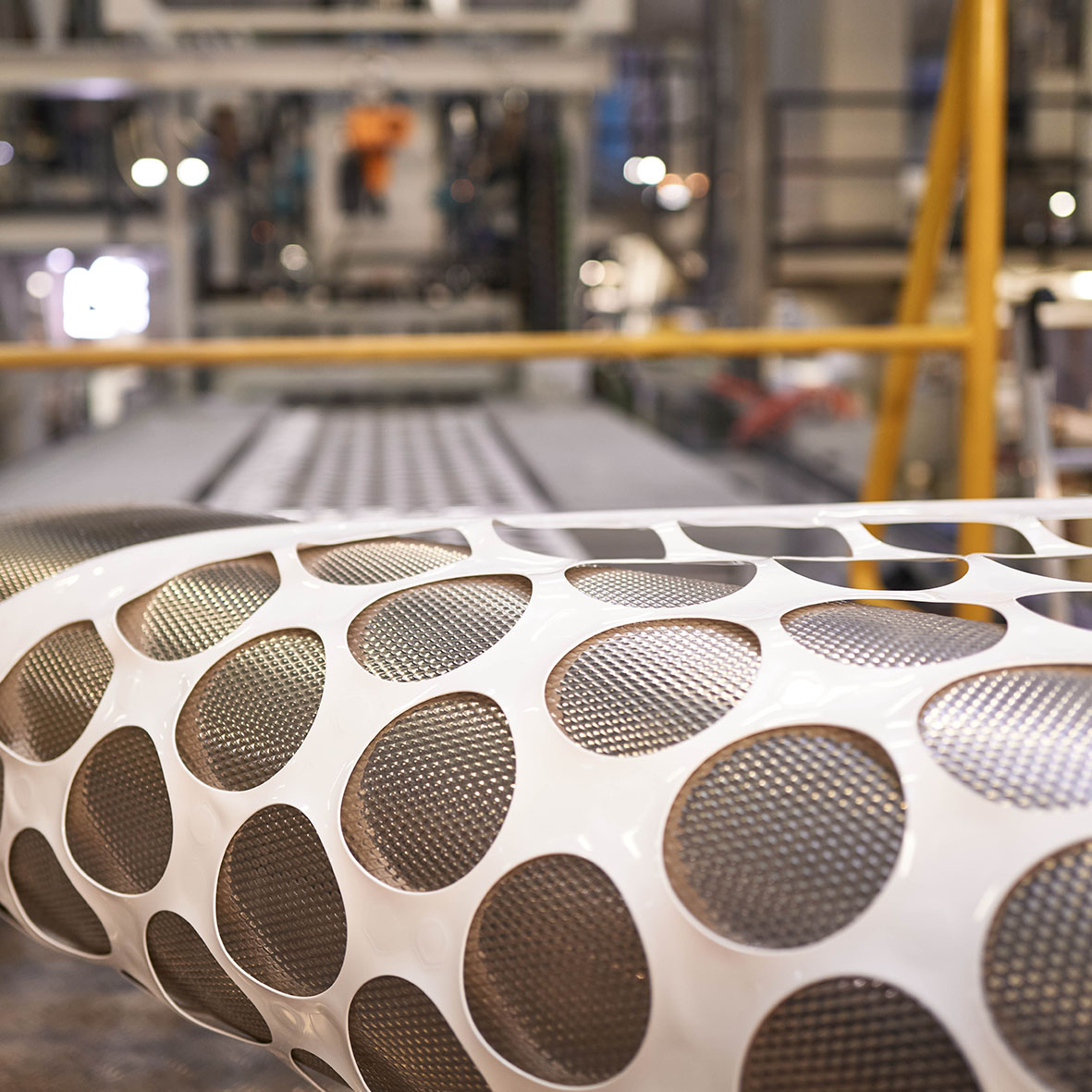

Thermoforming in-mold labeling (T-IML)

The first-ever plastic packaging solution to feature decorated, high-barrier, and retortable containers. The packaging is highly suitable for premium-branded products that require a long shelf-life and that need to withstand retort or hot-fill processes.

The in-mold labeling process is integrated directly with thermoforming.

PERFECT SOLUTION FOR:

| Dairy |

| Convenience Food & Spreads |

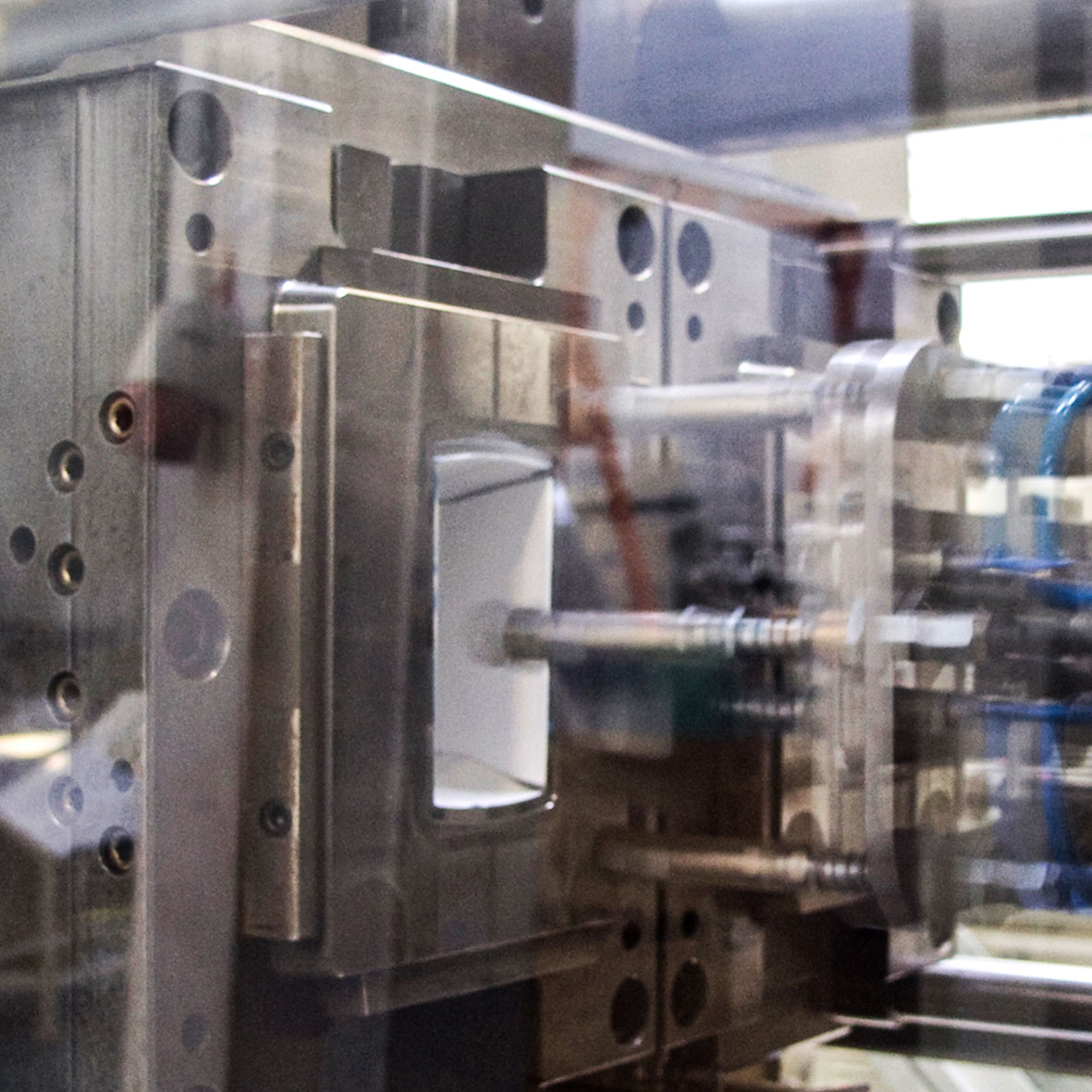

Injection molding

Injection molding completes our processes. This process precisely creates even the most specifically shaped packaging. This technology allows the IML (in-mold labeling) decoration technique: insertion in the mold of high quality printed labels which allow production in one step a high quality decorated product. This technology also allows improving product safety by temper evident solutions.

Our Solutions for:

| Dairy | Ice cream cups and containers |

| Convenience Food & Spreads | Cups, trays, tubs, lids (all can be with or without IML) |

| Food Service | Reusable cold and hot beverage cups |

Injection compression molding

Injection compression molding is a new injection process that reduces injection pressure and allows to decrease the thickness of container walls. Like regular injection molded packaging, this solution is characterized by freedom of shape, and a high level of mechanical properties such as robustness (top load) and safety (tamper evidence). Packaging can be manufactured on hydraulic, hybrid, or fully electric machines, with no compromise on the production speed. With this process, we can achieve weight reduction and saving of up to 20% of the materials.

Our Solutions for:

| Convenience Food & Spreads | Lightweight tubs with in-mold decoration |

Continuous compression molding

Continuous compression molding enables us to manufacture closures with induction heat seals and EPE (Expanded Polyethylene) liners with high efficiency, flexibility, and speed-to-market.

Less energy and maintenance are required in common injection molded technology, and with 100% camera control, caps are produced without an injection point and with a considerably lower weight.

Our solutions:

Caps and Closures

Blow-molding

Blow-molding is well suited for both low and high production rates, and a wide selection of materials is available for blow-molding, in addition to both standard and irregular shapes.

Our solutions:

Blow-molded bottles, cans, and canisters

DUOSMART®

DuoSmart® is a combination of a thermoformed plastic inlet and a wrapped around decorated paper banderole. This solution combines the advantages of both plastic and paper while presenting a functional, secure, and highly decorative packaging solution. The plastic inlet secures food protection, allows efficient machinability and efficient lidding foil sealing. The paper banderoles are offset printed to ensure perfect color reproduction. They also allow more space for branding and other special effects, such as embossing or hot stamping. Moreover, DuoSmart® provides a more sustainable solution, with no compromise on the quality or safety of the packaging.

DuoSmart® Solutions for:

| Dairy and Ice Cream |

| Convenience Food (incl. Dry Food, Spreads) |

| Food Service |

| Pet Food |

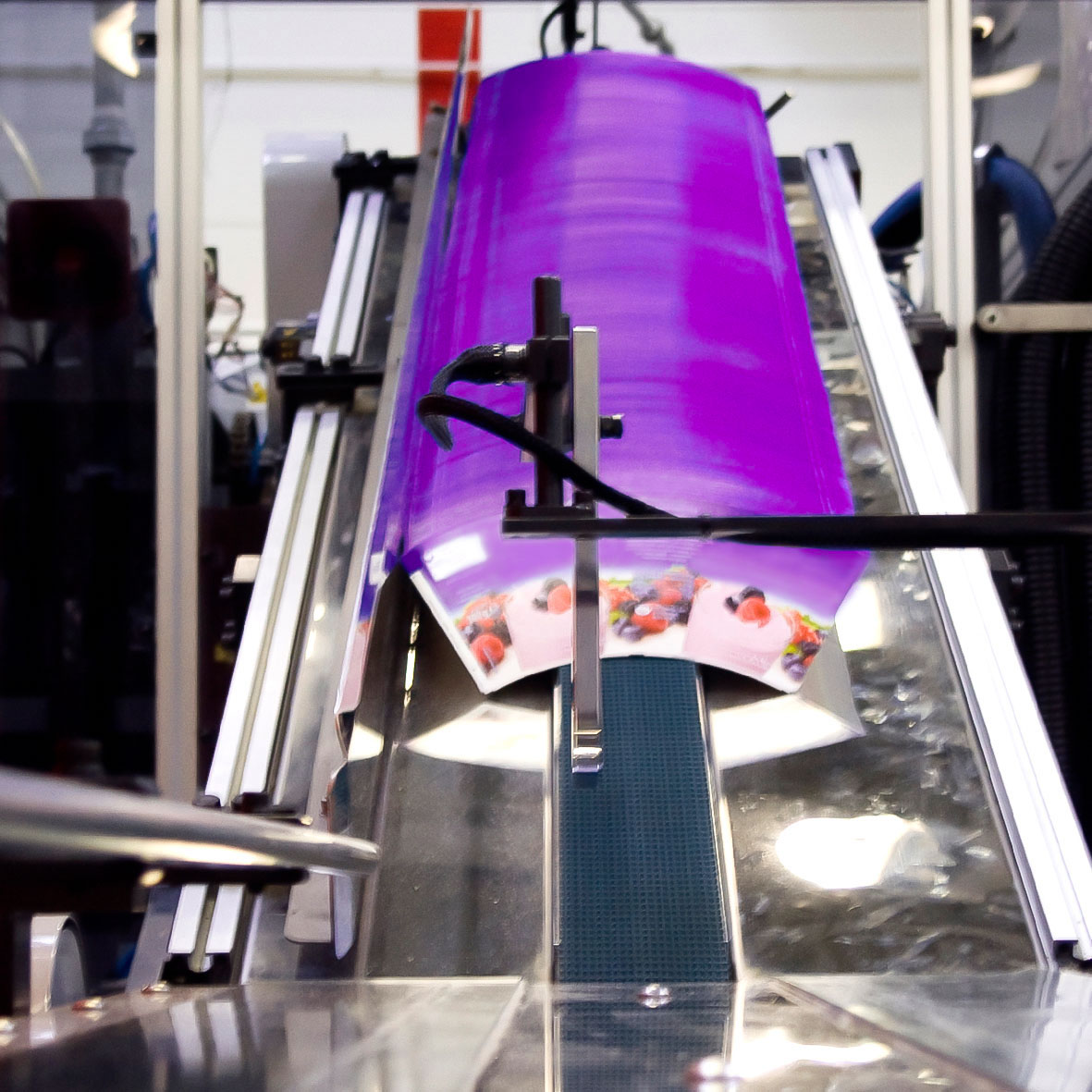

Decoration techniques

We offer a complete range of decoration technologies to ensure excellent product differentiation, as well as instant consumer appeal, including:

- Dry offset printing

- Rotogravure sheet printing (for pre-printing lids)

- Adhesive labeling

- Shrink sleeving

- Lamination

- Embossing

- Paper segments wrapping

- In-mold labeling in injection or thermoforming